Publications

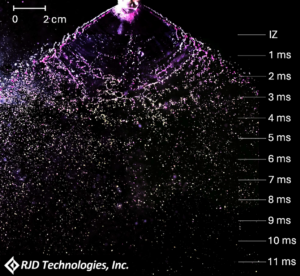

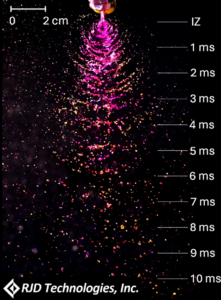

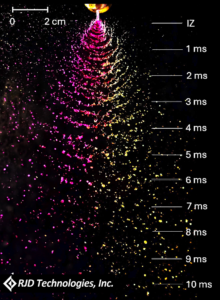

Demyanovich, R.J., 2025, Cold flow comparison of impinging-sheet injectors with impinging-jet injectors. AIAA Paper 2025-2285 . https://arc.aiaa.org/doi/10.2514/6.2025-2285

Demyanovich, R.J., 2024a, Experimental study and turbulence dissipative scale modelling of the rapid micromixing of impinging, paper-thin sheets of liquids. Chemical Engineering Research and Design 206, pp. 347-366. https://doi.org/10.1016/j.cherd.2024.04.060

Demyanovich, R.J., 2024b, High energy dissipation rates from the impingement of free paper-thin sheets of liquids: Determination of the volume of the energy dissipation zone. Chemical Engineering Science 294, 120128. https://doi.org/10.1016/j.ces.2024.120128 https://doi.org/10.48550/arXiv.2403.08122

Demyanovich, R.J., 2021a, High energy dissipation rates from the impingement of free paper-thin sheets of liquids: A study of the coefficient of restitution of the collision. Chemical Engineering Science: X 12:100113. https://doi.org/10.1016/j.cesx.2021.100113

Demyanovich, R.J., 2021b, On the impingement of free, thin sheets of liquids – A photographic study of the impingement zone. AIP Adv. 11. https://doi.org/10.1063/5.0040336

Demyanovich, R.J., Bourne, J.R., 1992, Secondary mixing of Impinging Sheets. Chem. Eng. Commun. 113, pp. 133-146. https://doi.org/10.1080/00986449208936008

Demyanovich, R.J., Bourne, J.R., 1992, Impingement-sheet mixing of liquids at unequal flow rates. Chem. Eng. Process. 31, pp. 229-239. https://doi.org/10.1016/0255-2701(92)87015-9

Demyanovich, R.J., 1991, Production of commercial dyes via impingement-sheet mixing. Part II. Results of laboratory experiments. Chem. Eng. Process. 29, pp. 179-183. https://doi.org/10.1016/0255-2701(91)85018-J

Demyanovich, R.J., 1991, Production of commercial dyes via impingement-sheet mixing. Part I. Testing of a device suitable for industrial application. Chem. Eng. Process. 29, pp. 173-177. https://doi.org/10.1016/0255-2701(91)85017-I

Demyanovich, R.J., 1991, Absorption of carbon dioxide by impinging, thin liquid sheets. Chem. Eng. Commun. 103, pp. 151-166. https://doi.org/10.1080/00986449108910868

Demyanovich, R.J., Bourne, J.R., 1989, Rapid micromixing by the impingement of thin liquid sheets. 2. Mixing study. Ind. Eng. Chem. Res. 28, pp. 830-839. https://doi.org/10.1021/ie00090a027

Demyanovich, R.J., Bourne, J.R., 1989, Rapid micromixing by the impingement of thin liquid sheets. 1. A photographic study of the flow pattern. Ind. Eng. Chem. Res. 28, pp. 825-830. https://doi.org/10.1021/ie00090a026